Chipotle Ingredient Shortages: Supply Chain Struggles Respirate Through Every Burrito

Chipotle Ingredient Shortages: Supply Chain Struggles Respirate Through Every Burrito

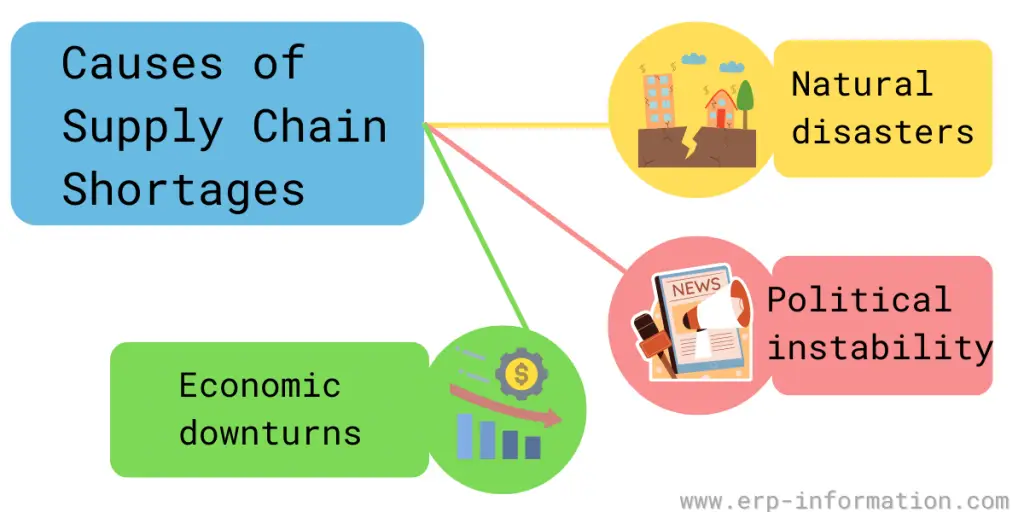

When Chipotle’s iconic menu faces unexpected ingredient delays, more than just customer patience is tested—supply chain resilience becomes the unseen hero. In recent months, the beloved fast-casual chain has grappled with significant shortages across key components, from organic turkey to housing seasonal produce, disrupting operations and sparking operational challenges. These disruptions are not isolated hiccups but symptoms of broader systemic pressures affecting food sourcing, labor availability, and climate volatility.

Behind the simple slogan “Better Ingredients. Better Food. Better World,” Chipotle’s supply chain reveals cracks that ripple through kitchens nationwide.

At the heart of these shortages lies a complex interplay of agricultural instability, transportation bottlenecks, and shifting consumer demand. The company relies heavily on region-specific, non-GMO, and organic ingredients—choices that enhance flavor and sustainability but increase vulnerability to environmental shocks. “We source foods from small, committed farmers who may lack the capacity to recover quickly from droughts or floods,” explained a Chipotle food sourcing report from early 2024.

“This ethos is central to our brand, yet it creates fragility when weather extremes disrupt harvests.”

Weather-related crop failures have been a primary driver. Prime agricultural regions—such as the Southwest for corn, the Midwest for pork, and Northern California for citrus—have experienced unprecedented droughts and heatwaves. These conditions have reduced yields and delayed planting cycles.

For high-demand items like the Black Beans & Rice Burrito, supply gaps mean reduced menu consistency. “We’ve had to temporarily rotate similar proteins or adjust portion sizes when turkey availability dips,” says a restaurant operations manager. “Customer trust depends on consistency, so even small disruptions matter deeply.”

Compounding these agricultural pressures is a strained logistics network.

Border delays, shipping container shortages, and rising fuel costs have increased transit times and heightened uncertainty. Fresh produce, which constitutes over 60% of Chipotle’s ingredient profile, is especially sensitive to shipping disruptions. “Perishables move fast—when ocean freight slows, our pull-and-resupply model seizes,” the sourcing lead noted.

“Even a two-week delay can lead to out-of-stocks on popular ‘Cultivated Veggie Bowl’ or ‘Crispy Chicken Lettuce Wrap.’”

Labor shortages further deepen the crisis. Staffing deficits in farms, processing plants, and distribution hubs slow raw material flow. The pick-and-pack operations essential for fresh prep face delays as workers become scarce.

“We’re prioritizing consistent ingredient flow but can’t move forward without reliable labor across the chain,” an executive summarized. “Every shortage feels like a domino—delayed delivery, reduced menu options, growing customer frustration.”

Not all shortages are supply-side, however. Shifting consumer preferences toward local, ultra-fresh, and seasonal ingredients have forced rapid adaptation.

While Chipotle champions “responsibly sourced” foods, guaranteeing year-round consistency is increasingly challenging. “We want the freshest tomatoes in winter, but indoor farming and climate-controlled logistics aren’t yet scalable enough,” the chief culinary officer noted in a public forum last year. “Our goal is to balance ideals with operational reality.”

The impact extends beyond smooth kitchen operations.

Ingredient shortages have strained inventory management, compelling tighter scheduling and more frequent supplier negotiations. Marketing campaigns promoting signature items gain urgency, but restaurant managers report canceled promotions when staple components vanish. “We used to launch seasonal items confidently,” a franchisee relayed anonymously.

“Now, we monitor spice and protein inventories like quarter

Related Post

Doug DeMuro Net Worth and Earnings

Who Won World War I? The Victorious Powers and the Shaping of a New World Order

WWE RAW February 5 2024 Preview Confirmed Matches Start Time and How to Watch

Zip Codes in Lubbock, TX: The Geographic Backbone of West Texas’ Largest City