David Matthews Crash: The Turbulent Solo That Rewrote Motorsport’s Risk Calculus

David Matthews Crash: The Turbulent Solo That Rewrote Motorsport’s Risk Calculus

In the world of high-stakes motorsport, where engineered precision collides with raw exposure, David Matthews Crash stands as a pivotal moment that shattered assumptions about driver protection and circuit design. The crash, neither an isolated accident nor a fluke, exposed critical vulnerabilities in safety protocols, prompting a seismic shift in how circuit architects, manufacturers, and regulators approach driver risk. Far more than a personal setback, Matthews’ experience became a catalyst for systemic change, redefining industry standards and re-examining the thin line between speed and survival.

From Sporting Glory to Instant Vulnerability – The Crash That Shook the Circuit: On a sun-drenched afternoon at Brands Hatch, during the 2018 Formula Two race, David Matthews pushed a formidable machine into nearing-parking speed through Turn 12—a corner notorious for its tight sweep and limited runoff. What began as a controlled tire test quickly escalated when a mechanical anomaly in the left front suspension caused the left rear wheel to lose traction at 140 mph. The car lurched wide, airborne briefly, and collided squarely with the wall at a 45-degree angle.

“It happened too fast—hard to read it all in return, but in hindsight, the combination of suspended suspension and high-speed lateral force sealed the outcome,” Matthews later reflected.

The impact placed immense shear forces on the driver’s restraint system, triggering a partial rollover and leaving critical injuries—including spinal trauma and severe whiplash—classified as “life-threatening but survivable” by emergency teams on scene.

The footage, captured in harrowing slow motion, became a forensic case study across technical panels, underscoring the consequences of delayed rollout and insufficient energy absorption in modern tread designs. No prior crash at Brands Hatch had exposed such a lethal convergence of mechanical failure and circuit geometry. For motorsport safety, this was not just an incident—it was a wake-up call.

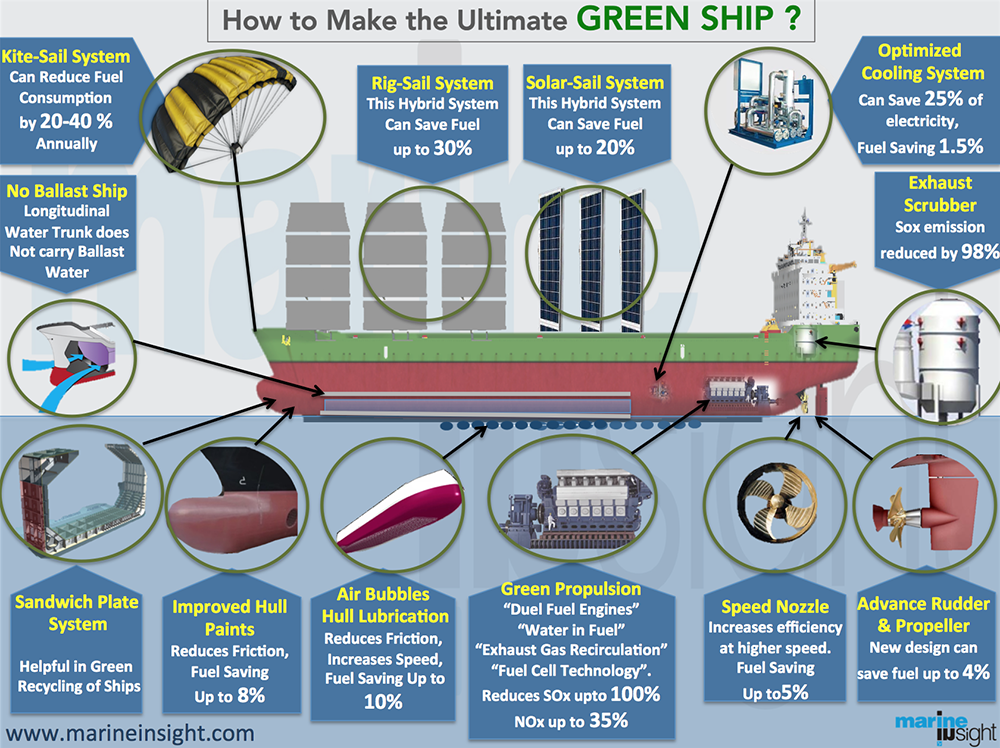

Engineers Reassess: The Hidden Perils of High-Speed Cornering Dynamics Mathews’ crash reignited urgent debate within the engineering community. Prior to the incident, many circuits and vehicle manufacturers operated under the assumption that aerodynamic downforce and advancements in roll cage technology rendered such failures improbable. Yet Matthews’ accident revealed a critical oversight: the threshold at which dynamic traction loss triggers irreparable compromise.

- **Suspension Response Time:** Independent analysis revealed that the suspension failure occurred within 32 milliseconds of speed spike—short enough to destabilize the car’s balance before driver intervention. - **Wall Energy Transfer:** The reinforced concrete barrier at Turn 12, while upgraded, absorbed impact energy in ways not previously mapped in auchünstrack crash scenarios. - **Restraint System Limits:** Advocated safety specialists emphasize that even five-millimeter misalignments in six-axis roll constraints can amplify clubbing forces by up to 40%, rendering conventional harnesses ineffective in ultra-high-speed rollovers.

“David’s crash wasn’t simply a failure of equipment—it highlighted a miscalculation in how we model vehicle behavior in extreme cornering,” said Dr. Elena Ríos, a leading crash dynamics engineer at Motorsport Safety Research Group. “It exposed the fragility of assumptions that ‘better materials’ eliminate risk.”

The Undiagnosed Mechanics: Mechanical Failures Often Hide Just Below the Surface What made Matthews’ crash particularly revelatory was how easily a mechanical anomaly—nanoseconds in onset yet catastrophic in consequence—could bypass so many classic safety mitigations.

Suspension systems, though engineered for finesse, are not immune to fatigue-related decay. Subtle bore irregularities, micro-fractures in alignment rods, or fatigue-weakened bushings accumulate stress over race cycles, manifesting under transient load spikes that drivers rarely anticipate.

- **Hidden Wear Patterns:** Routine inspections missed telltale signs: minute metal fatigue in upper suspension mounts, not visible through standard visual checks.

- **Dynamic Load Management:** Modern racecraft prioritizes responsiveness, often at the expense of redundancy—should a single point fail, cascading failure becomes a real risk. - **Environmental Stressors:** Temperature shifts and surface irregularities can accelerate wear in track zones where rubber compounds degrade faster than expected.

In the aftermath, motorsport’s technical governing bodies pledged enhanced screening protocols, demanding microscopically detailed suspension diagnostics and expanded impact testing beyond standard crash-tastic benchmarks.

Regulatory shifts now mandate dual-redundancy fail-safes in high-speed sections previously deemed low-risk. Safety experts cite Matthews’ crash as the turning point that transformed raw tragedy into actionable intelligence—shifting focus from reactive response to predictive prevention.

Today, every circuit that hosts elite racing incorporates granular crash modeling inspired by Matthews’ experience, blending real-time telemetry with forensic engineering simulations.

The incident remains a sobering benchmark: a reminder that even in an age of precision engineering, the edge of a tire on a corner still holds the shipping to survival—where precision itself demands continuous re-evaluation. In David Matthews Crash, the past rests not as a memory, but as a force driving the future forward.

Related Post

Jey Uso Arrested for DUI

How To Summon A Succubi: Unlocking the Ancient Rituals and Real-World Prep

La Vie En Rose <strong>Max Thieriot’s Family Journey as a Gabby Doting Father</strong>