How Trains Change Tracks: The Engineering Behind Seamless Rail Transitions

How Trains Change Tracks: The Engineering Behind Seamless Rail Transitions

Trains glide silently along rail tracks, a seemingly effortless movement enabled by a complex interplay of infrastructure, technology, and precise coordination. Yet behind every train’s smooth departure and precise routing lies a series of deliberate decisions—and engineering feats—known collectively as "How Trains Change Tracks." This process, though often invisible to passengers, is fundamental to maintaining efficient rail networks, minimizing delays, and ensuring safe operations across global transit systems. From track switching mechanisms to signal coordination, the methodology behind trains changing rails combines tradition with innovation.

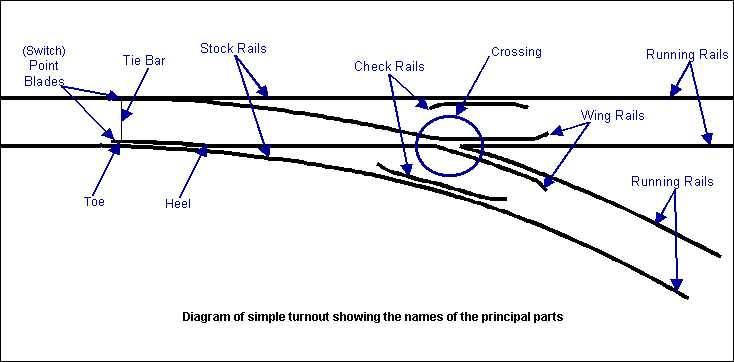

At the heart of track switching is the rotary switch, commonly known as a turnout.

The Mechanics Behind Track Switching

These device-like structures reconfigure the path of a train by physically redirecting keys within the rail network’s branching junctions. A basic turnout consists of secured rails—called straining rails—shifted into place by driven crossovers and switch rods.When activated, these components realign the track so a locomotive enters one branch instead of the main line. \begin{itemize>

\begin{h3>How Signals Guide Track Changes Trains change tracks only under strict signal supervision. Each section of track is monitored by fixed signals되고, red or green indicators showing whether a switch is clear. When a train approaches a junction, transponders relay real-time data to centralized control systems.

Automation now enables, and optimizes, these transitions.

Digital interlocking not only prevents conflicting movements but also harmonizes brake release with switch activation. This synchronized timing allows trains to enter alternate tracks without braking—boosting efficiency and reducing energy use. \begin{itemize>Rail infrastructure is built with multiple layers of protection: physical locks that mechanically interlock tracks, dual signal pathways that verify switch status, and remote override controls for emergency interventions. These safeguards ensure that even in high-pressure conditions—such as peak travel hours or unexpected maintenance—trains maintain safe passage through junctions. Their design honors both historical rail engineering milestones and 21st-century innovation.

The rotary switch remains foundational, yet integrated with IoT sensors and predictive maintenance algorithms that anticipate wear before failure occurs. This evolution reflects a broader trend: railways worldwide are transforming from static tracks into intelligent networks capable of adaptive routing. Ultimately, every train’s journey hinges on a quiet ballet of switches, signals, and systems working in concert—each decision calculated, each track change executed with mechanical precision.

Far from being automatic, changing tracks demands a deep synergy of engineering rigor and digital intelligence, ensuring that rail travel remains reliable, safe, and scalable in an evolving transportation landscape. This understanding reveals that behind the seamless flow of trains lies a world of deliberate mechanics, strategic oversight, and relentless optimization—proof that even the most familiar technologies depend on invisible, yet indispensable advancements.

Related Post

.jpg/revision/latest/scale-to-width-down/1200?cb=20230720070417)

Draco Malfoy: The Complex Legacy of a Potter Cast

Meet The Actor Who Breathed Life Into Ragnar: The Man Behind the Viking Legend

Devon Bostick’s Rise: From Elimination Show Star to Television Maverick

What Industry Leaders Are Saying About the Contents of the 8 Leaked Anna Faith Secretse280A6 — Insights Reveal A Cultural and Legal Cautionary Tale