Short Edge vs Long Edge Printing: A Expert Comparison That Defines Precision in Modern Production

Short Edge vs Long Edge Printing: A Expert Comparison That Defines Precision in Modern Production

In the evolving landscape of printing technology, two critical edge definitions—short edge and long edge printing—govern everything from product packaging to fine art reproduction, directly influencing visual appeal, structural integrity, and manufacturing efficiency. Understanding the nuanced difference between these two approaches is essential for designers, publishers, and manufacturers seeking to optimize output quality and operational workflows. This comprehensive guide breaks down the technical aspects, application contexts, and practical trade-offs of short edge versus long edge printing, offering clear, evidence-based insights to inform strategic printing decisions.

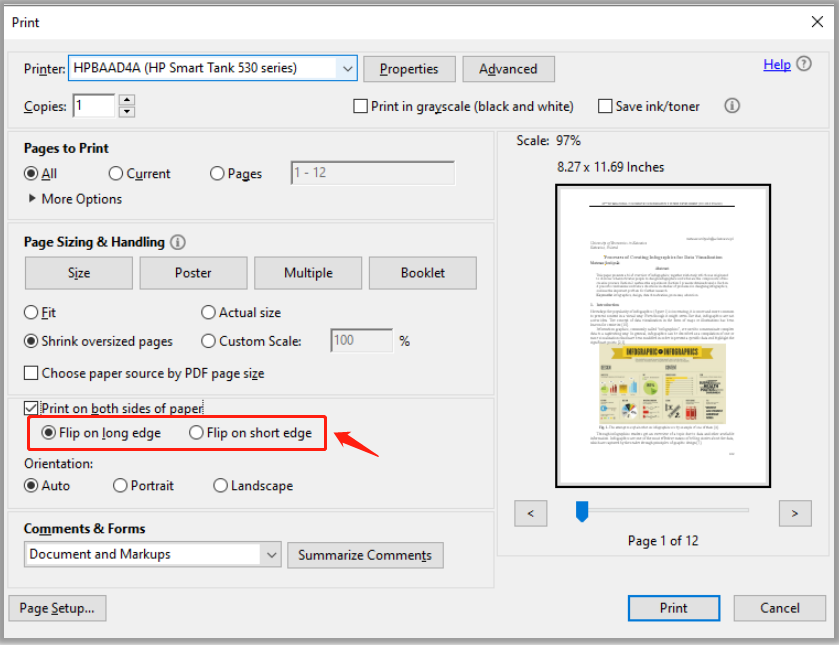

At its core, the distinction lies in the orientation of a printed surface relative to a workpiece’s longitudinal edge. Short edge printing focuses on printing along the narrower side of a material—typically a sheet, tube, or roll—where the shorter dimension defines the active printing surface. Long edge printing, conversely, utilizes the longer edge, leveraging greater width to maximize image or text coverage and alignment precision.

This seemingly simple division has profound implications on print quality, material stability, and machine compatibility. While long edge printing often delivers superior resolution across broader surfaces, short edge techniques remain indispensable for compact, scalable, or curved formats.

The Mechanics Behind Short Edge and Long Edge Printing Systems

Modern printing presses—ranging from digital inkjets to offset lithography—adapt their mechanics to maximize edge efficiency. In short edge printing, the press aligns material along the shorter side with precision guide systems to prevent misalignment during feed.This orientation limits print width but enhances edge consistency, especially critical for packaging where rigid corners and sharp labels depend on clean, vertical printing. Short edge machines often feature dual-speed rollers and short-run optimizers, enabling rapid setup and high repeatability for labels, trays, and folded inserts.

Long edge printing, in contrast, exploits extended width to support larger images, barrier tags, or full-color banners running across a material’s length.

Devices handling this method employ extended cylinder configurations in rotogravure or legal-size offset plates, ensuring even ink distribution and edge-to-edge color transfer. Because long edge systems require stable, unyielding material reinforcement—often using double-sided tapes or nested superbands—the alignment tolerances and roller calibration become stricter, demanding advanced moisture control and tension regulation to avoid edge warping or discoloration.

Key Technical Considerations

- Edge Accuracy and Alignment: Short edge printing excels in tight, repeatable tolerances, crucial for overstock labeling and precision engineering uses. The shorter exposure distance reduces cumulative misregistration errors.

- Material Compatibility: Short edge processes work best with flexible substrates like plastic films, foil-wrapped pouches, and small paper formats.

Long edges favor rigid materials—board, acrylic, or metalized sheets—where structural stability minimizes load-induced edge distortion.

- Peak Print Quality: Long edge systems offer advantages in high-volume production of large-format banners and continuous rolls, enabling seamless color saturation and saturation consistency across extended surfaces.

- Setup Efficiency: Short edge presses reduce setup time for small batches and multi-face projects, improving throughput in high-mix environments. Long edge operations often require longer pre-press calibration and material nesting, increasing downtime.

Quality metrics further distinguish the two. Short edge printing ensures crisp, unmisshadowed text at narrow edges, vital for bar-code readability on blister packs or appointment cards.

Meanwhile, long edge printing maintains uniform tint depth and minimizes edge fringing on wide banners, where even ink flow and low register shift are non-negotiable. Print density and gloss retention often favor long edge applications due to extended exposure and broader blanket coverage, minimizing dot gain at larger scales.

Applications Driving Demand

Short edge printing dominates industries requiring precision and compact form factors. Common uses include:

- Food and pharmaceutical labels printed on blister packs and sachets, where legibility and edge clarity directly impact compliance and brand perception.

- Flexible packaging: inserts, end-caps, and margin labels benefitting from tight corners and professional finishing.

- Printed circuit boards and copper tape, where electrical insulation and registration precision depend on unblemished short edges.

- Kid-safe packaging requiring discreet, high-contrast labeling within constrained dimensions.

Long edge printing is the pillar of large-scale visual communication and industrial packaging.

Applications include:

- Point-of-sale displays, vehicle wraps, and building signage spanning meters in width.

- Flexographic banners for trade shows, museum installations, and event promotions.

- Corrugated board printing for e-commerce and retail, where full-color graphics on larger sheet sizes drive consumer engagement.

- Retail shelf talkers and shelf-backed ads printed on wide board stocks to maximize brand visibility.

Operational and Economic Trade-offs

The choice between short and long edge printing is not merely technical—it reflects broader business objectives. Short edge systems reduce capital and operational costs, ideal for facilities serving niche or customized markets with moderate print volumes. Their adaptability to small runs and rapid changeovers enhances agility in dynamic environments like print-on-demand or seasonal packaging campaigns.

Conversely, long edge printing demands higher initial investment, longer setup, and more rigorous material handling but delivers economies of scale at volume. Factory operators often justify the outlay by minimizing per-unit cost on large orders—critical for retail distributors or national brands saturating thousands of retail locations. Energy efficiency also varies: long edge high-speed presses consume more power per run, but their throughput can lower carbon footprint per printed piece in mass production contexts.

Navigating the Choice: Factors That Matter Most

Selecting between short edge and long edge printing requires a granular evaluation of project parameters:

- Volume: Short edge suits low-to-medium batches; long edge excels at high-volume runs.

- Format and Size: Compact docs, labels, or punch cards favor short edge; wide banners, rolls, and wideboards demand long edge.

- Material Type: Flexible films and foil pouches align with short edge durability needs; rigid boards or flexo-ready stock suits long edge applications.

- Quality Requirements: Edge sharpness, color uniformity, and alignment precision guide the decision—long edge for consistent banners, short edge for intricate detail on small formats.

Additionally, technological evolution continues reshaping the boundary between these techniques. Hybrid presses now combine versatile edge handling, using intelligent load sensors and adaptive registration to bridge short and long edge capabilities. Digital advancements also enable shorter proofs and mobile setup tools, reducing lead times across both modalities.

The Future of Edge Subtraction

As markets grow more specialized and sustainability concerns intensify, the focus shifts toward maximizing each edge’s potential with minimal waste and energy use. R&D efforts emphasize dynamic edge calibration systems, predictive maintenance via IoT-integrated presses, and advanced inks with self-leveling properties that reduce edge blur. Whether crafting the delicate edge of a medication blister or

Related Post

Minnesota Twins Vs Dodgers Match Player Stats

Special Feature: Exploring Filippa Coster-Waldau's Determined Ascent in the Cinematic World

Adam Sandler’s Military Roots: How a Serviceman’s Family Legacy Shaped a Hollywood Icon

Discovering Josephine Jackson: A Full Scrutiny of a Current Figure