The Future Is Measured in Precision: How Automatic Size Is Revolutionizing Modern Design and Manufacturing

The Future Is Measured in Precision: How Automatic Size Is Revolutionizing Modern Design and Manufacturing

In an era where millimeters determine performance, Automatic Size has emerged as a transformative force across industries ranging from architecture and construction to microelectronics and consumer electronics. This precision-driven approach ensures components, fixtures, and systems are engineered, measured, and assembled with automatic accuracy—eliminating human error and accelerating production timelines. Unlike manual dimensioning, which relies on static tools and skilled labor, Automatic Size leverages sensor technology, machine learning, and real-time feedback to dynamically assess and adjust measurements during every phase of manufacturing and installation.

### What Is Automatic Size and How Does It Work? Automatic Size refers to a suite of technologies that automatically detect, analyze, and apply precise dimensional data during production or installation. At its core, the system integrates advanced sensors—such as laser scanners, vision systems, and 3D profilometry—with intelligent processing algorithms.

These tools capture spatial data with micron-level resolution, instantly comparing physical measurements against digital blueprints or design tolerances. When discrepancies are found, automated systems trigger real-time corrections, recalibrating machinery or adjusting placement to maintain alignment and fit. The process typically unfolds in three phases: - **Data Acquisition:** High-resolution sensors capture exact dimensions and spatial relationships.

- **Analysis & Comparison:** Algorithms process data instantly, cross-referencing it with CAD models or BIM (Building Information Modeling) frameworks. - **Actionable Output:** Deviations are automatically flagged, and in smart setups, adjustments are executed through connected tools or robotic arms. “The precision of Automatic Size minimizes fitment errors that once compromised structural integrity and operational efficiency,” says Dr.

Elena Marquez, a senior engineer in advancements in industrial metrology. “It’s not just about checking dimensions—it’s about ensuring they’re always correct, exactly when and where they matter.” ### Applications Across Key Industries In architectural and construction sectors, Automatic Size is streamlining complex installations. From pre-fabricated curtain walls that align seamlessly on skyscrapers to precisely spaced structural beams, automated measurement systems reduce on-site modifications and rework.

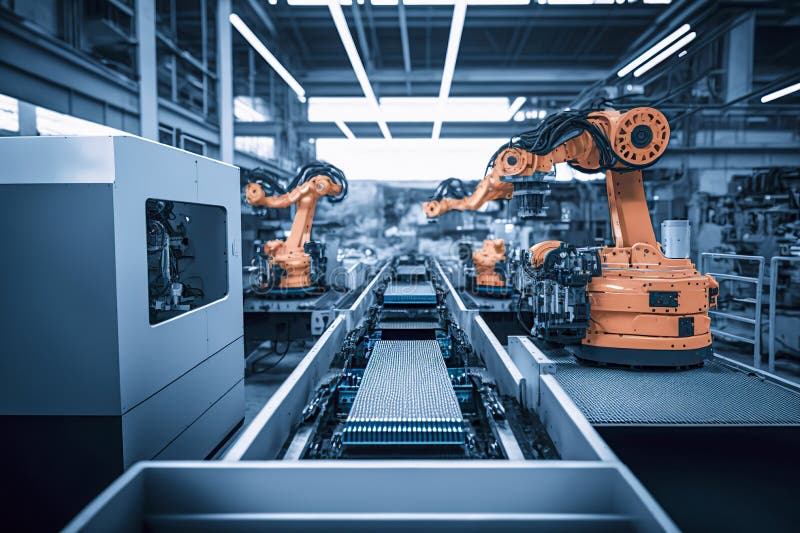

This translates to faster delivery times and lower costs—critical in today’s fast-paced urban development. In manufacturing, particularly in automotive, aerospace, and electronics, the standard for tight tolerances continues to shrink. Components must fit with micrometer-level accuracy to ensure safety, performance, and reliability.

Automatic Size systems monitor critical joints, solder points, and assembly interfaces in real time, enabling tight quality control without slowing output. Electronics and Microfabrication represent some of the most demanding frontiers. Semiconductor chips, for example, require placement accuracy within nanometers—so small that manual tools are obsolete.

Automated systems guide pick-and-place robots with sub-micron precision, drastically reducing defect rates and boosting device performance. Samsung has integrated such technology in its latest processor fabrication lines, citing significant improvements in yield and manufacturing repeatability. Healthcare and Medical Devices also benefit profoundly.

Surgical instruments, implants, and diagnostic equipment must meet stringent dimensional standards to ensure patient safety. Automated size verification during production ensures every stent, syringe pump, or orthopedic fixture conforms sharply to its intended form—eliminating even microscopic deviations that could compromise functionality. ### Advantages Over Traditional Methods The shift from manual to automatic sizing marks a paradigm shift in industrial practice.

Unlike conventional measurement techniques—where a technician uses calipers or tape measures—Automatic Size delivers consistent, repeatable results without fatigue or oversight. Key benefits include: - Reduced Error Margins: Automatic systems operate within deviations measured in microns, whereas human error can exceed 0.5 mm per measurement. - Faster Turnaround: Real-time feedback loops shorten inspection cycles from hours to seconds.

- Enhanced Traceability: Every dimension and adjustment is logged automatically, supporting compliance with ISO and ASME standards. - Cost Efficiency: Fewer rejects, less rework, and optimized material use lower overall production expenses. - Scalability: Ideal for high-volume manufacturing, where even small percentage improvements compound into massive gains.

Studies by McKinsey & Company estimate that manufacturers adopting automated size systems achieve up to 30% reduction in defect rates and 25% faster throughput—critical in competitive global markets. ### Challenges and Emerging Innovations Despite its promise, Automatic Size faces hurdles. High initial investment in sensor infrastructure and software integration can deter smaller firms.

Additionally, environments with lighting variation, reflective surfaces, or complex geometries challenge sensor accuracy—though recent advances in multi-spectral imaging and adaptive lighting mitigate these issues. Innovative startups and established tech leaders are rising to the challenge. Companies like OptoSys and Cognex are pioneering AI-enhanced vision systems capable of learning from thousands of dimensional datasets, improving recognition speed and error differentiation.

Meanwhile, the integration of Automatic Size with digital twins enables virtual testing before physical implementation—foreseeing and correcting potential misalignments digitally, further honing real-world precision. The merging of Automatic Size with Industry 4.0 infrastructure fuels smart factories where machines communicate seamlessly. Data flows instantly between laser scanners, robotic arms, and central control systems, enabling self-correcting workflows that operate with minimal human intervention—ushering in a new era of autonomous manufacturing.

Looking Ahead: The Road to Fully Automated Precision The future of dimensional accuracy lies in seamless automation—faster, smarter, and more intuitive. Automatic Size isn’t just a tool; it’s becoming foundational, reshaping how engineers design, builders construct, and manufacturers produce. As sensor technology evolves and AI models grow more predictive, the boundary between measurement and execution blurs.

The mantra “measure once, fit always” evolves into “measure, adjust, and trust—without ever looking.” Industry experts foresee a turning point where every component, no matter its complexity, will be verified and aligned with the precision of light itself. Automatic Size is no longer optional—it is the cornerstone of quality, safety, and innovation in a world where even the smallest deviation can have large consequences

Related Post

Tucker Carlson Elon Musk Full Interview: Inside the Visionary’s Most Controversial Conversations

The Global Rise of Industry: How Industrialization Spread Across the World

Alexis Zotos: Architect of Modern Media Strategy in a Shifting Digital Landscape

When Jackson Hole Meets Peak Moment: A Season’s Defining Across Seasons