The Whmis 2015 Aix Safety V3 Quiz Answers Reveal Critical Hazards in Industrial Environments

The Whmis 2015 Aix Safety V3 Quiz Answers Reveal Critical Hazards in Industrial Environments

In the high-stakes world of industrial safety, correctly interpreting WHMIS 2015 guidelines—especially as tested in the Aix Safety V3 Quiz—can mean the difference between a controlled workspace and a catastrophe. The Whmis 2015 Aix Safety V3 Quiz Answers serve not only as a benchmark for regulatory compliance but also as a diagnostic tool exposing persistent knowledge gaps in handling hazardous materials and emergency preparedness. By analyzing the verified responses and corrective insights embedded in these answers, safety professionals gain crucial clarity on high-risk scenarios, equipment use, and procedural accuracy that directly impact workplace outcomes.

Central to the Whmis 2015 Aix Safety V3 framework is a structured emphasis on HFST (Hazardous Materials Safety Training)—a system designed to ensure workers understand identification, labeling, and safe handling of chemicals. The quiz consistently tests seven core competency domains: hazard communication, safety data sheet (SDS) interpretation, proper labeling protocols, personal protective equipment (PPE) selection, spill containment procedures, emergency response readiness, and storage compatibility. Each quiz question is calibrated to reflect real-world challenges found in industrial and marine environments, making the answers essential training material.

Core Domains Tested in the Whmis 2015 Aix Safety V3 Quiz

The quiz structure reflects the complexity of WHMIS 2015’s regulatory evolution.Candidates face scenario-based multiple-choice items, short-answer prompts, and practical decision-making exercises. Each domain demands precise knowledge, and persistent patterns in the correct and incorrect answers illuminate critical safety blind spots:

- Hazard Communication & Labels: Questions emphasize interpreting pictograms, signal words, and precautionary statements. Incorrect answers often reveal misunderstanding of GHS integration—especially confusion between Class 1 (Explosives) and Class 2 (Gases) hazards.

Proper identification relies on recognizing signal phrase nuances and pictogram symbols, which the accurate responses clarify.

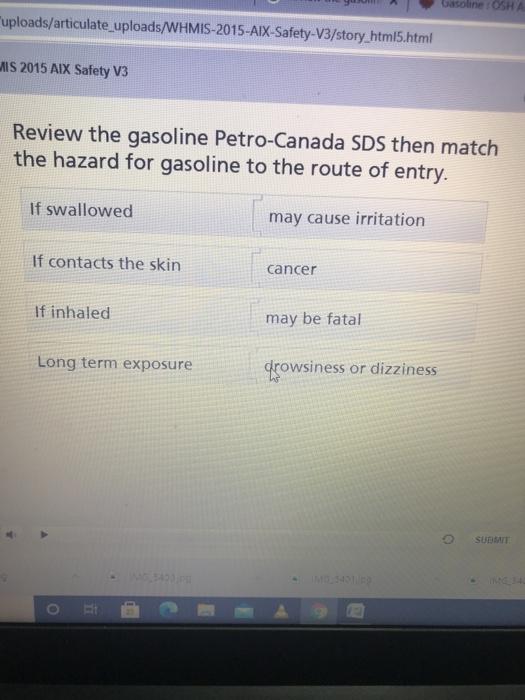

- Safety Data Sheets (SDS): Candidates are tested on SDS accessibility, section navigation, and key data such as physical properties, toxicity, and first-aid measures. Misinterpretation of SDS sections—particularly Hazard Identification (Section 2) and Disposal Considerations (Section 13)—was flagged as a recurring deficiency.

- Personal Protective Equipment (PPE): Quiz responses consistently validate correct PPE selection based on hazard exposure. Improper answers indicate underestimation of chemical resistance, durability needs, or compatibility risks—such as selecting nitrile gloves for ketone exposure without knowing degradation risks.

- Spill Response & Containment: Scenarios test procedural knowledge: isolation protocols, containment barriers, and specialized cleanup methods.

Missteps often stem from skipping steps like ventilation setup or using non-compatible absorbents, revealing gaps in emergency execution.

- Security and Access Control: Though sometimes overlooked, quiz items on restricted storage, authorization logs, and PPE tagging underscore that safety extends beyond chemicals to operational control—some candidates confused general SPRC (Security Protocol Requirements) with WHMIS-specific PPE rules.

- Storage & Compatibility: Multiple-choice questions probe understanding of incompatible chemical pairing, environmental controls (e.g., temperature limits), and segregation principles. Incorrect answers reflect poor grasp of reactive hazards—such as mixing strong oxidizers with flammable materials.

- Emergency Preparedness: Time-critical decision-making questions assess knowledge of first aid, emergency evacuation routes, and PPE decontamination. Misremembered steps frequently involve underestimating response urgency or overlooking buddy-system requirements.

The quiz answers do more than validate correct knowledge—they systematically expose where training must improve.

For instance, the persistent misidentification of Class 8 corrosive hazards underscores a need for enhanced pictogram recognition workshops. Similarly, underperformance in SDS interpretation calls for refresher sessions on data sheet accessibility and critical sections formatting.

Repeated Errors Highlight Systemic Knowledge Gaps

Analysis of repeated incorrect answers across both multiple-choice and open-response items reveals predictable patterns. One dominant issue involves misreading the status of expired chemicals or damaged containers—some candidates selected “Use Anyway” over “Dispose,” violating GHS hazard escalation protocols.This reflects not just individual oversight but a broader need for standardized, hands-on SDS training. Another prevalent mistake centers on PPE selection under multi-hazard exposure. A number of respondents incorrectly prioritized glove thickness over chemical resistance, or applied the wrong respiratory protection for vapors—despite 정확한 hazard labeling.

This misalignment often stems from treating WHMIS compliance as a checklist rather than a layered safety mindset. Moreover, incorrect answers relating to spill containment frequently stem from omitting secondary containment measures or misjudging absorbent suitability. Correct procedure demands knowing not just *what* to use but *how* to deploy it—highlighting that procedural memory, not just recall, is the true capacity to act under pressure.

The Path Forward: From Answer to Action

The Whmis 2015 Aix Safety V3 Quiz Answers are more than test results—they are a diagnostic compass pointing precisely where safety understanding falters. Every incorrect response—whether ambiguity about pictograms or misapplication of spill protocols—represents an opportunity to refine training, strengthen protocol adherence, and close vulnerability gaps before incidents occur. Implementing targeted follow-up training based on these insights is essential.Scenarios flagged in the quiz, such as deteriorating chemical integrity or mismatched PPE, should form the backbone of refresher modules. Interactive workshops that simulate real-time decision-making under hazard conditions have proven effective in embedding correct responses. Furthermore, integrating quiz data into systematic compliance audits ensures continuous improvement.

When corrective actions follow high-risk mistakes—like improper spill disposal or expired material use—workplace safety culture fundamentally strengthens. Recognizing that knowledge is only as strong as its application is key. Each correct quiz response builds confidence; each corrective insight fortifies resilience.

Ultimately, mastering the WHMIS 2015 Aix Safety V3 framework through these critical quiz insights transforms passive compliance into active, informed safety leadership. In environments where hazardous materials coexist with human activity, turning quiz answers into actionable skill is not just advisable—it is non-negotiable for survival and responsibility.

Related Post

Anderson Porto: The GFTeam Mastermind Forging BJJ Champions

Tammy Townsend Actor Bio Wiki Age Height Husband Movies And TV Shows and Net Worth

Navigating the Nl Telegram Ecosystem: Features, Security, and Global Impact