Truck 16 Wheeler: The Powerhouse Reshaping Heavy-Duty Freight Transport

Truck 16 Wheeler: The Powerhouse Reshaping Heavy-Duty Freight Transport

In the ever-evolving world of logistics and transportation, the Truck 16 Wheeler stands as a defining workhorse—engineered for endurance, efficiency, and innovation. Defined by its classification as a Class 6 heavy-duty truck under the Federal Vehicle Classification Standard (FVCS), the 16-wheeler embodies the backbone of industrial and interstate freight movement. With a gross vehicle weight averaging between 70,000 to over 100,000 pounds and a stabilizing array of 16 axles, this vehicle isn’t just a truck—it’s a complete mobile platform designed to handle immense payloads across rugged terrains and demanding schedules.

<

“Our 16-wheeler platforms are engineered for real-world resilience,” notes Sarah Mitchell, Chief Operations Engineer at TransLift Logistics. “They balance raw power with precision routing and driver ergonomics, turning what once was brute-force hauling into a sophisticated, data-driven operation.” The 16-wheeler’s layout maximizes cargo capacity through strategic Door-to-Door design, typically featuring six rear axles and multiple tandem or multi-axle configurations. This arrangement not only supports higher Gross Vehicle Weight Ratings (GVWR) but also distributes ground pressure evenly, minimizing soil and infrastructure impact—particularly vital when operating on remote job sites or environmentally sensitive corridors.

<

Advanced driver assistance systems, including adaptive cruise control, lane departure warnings, and collision mitigation, enhance safety—critical when managing 80-foot trailers with such substantial mass. These smart systems contribute to an industry-wide push toward automation and connected logistics. For example, Volvo’s FL Electric 16 Wheeler combines a high-capacity battery with hybrid drivetrains and smart power management, delivering up to 300 miles of electric-only range for urban delivery routes while retaining diesel backup for long hauls.

This dual-mode capability reflects a broader trend: the 16-wheeler evolving from a fossil-fuel icon into a versatile, sustainable transport solution. <

In municipal waste management, specialized models transport heavy containers and recycling loads efficiently through urban cores with reduced noise and emissions due to modern emission compliance standards like EPA III and Euro VI. “What really distinguishes the 16 Wheeler is its adaptability,” explains Charles Reed, Director of Heavy Transport at Prairie Freight Solutions. “It’s not just about moving goods—it’s about doing so reliably, even when conditions change.

Whether navigating icy mountain passes or desert highways, these trucks maintain consistent performance under pressure.” Industry certifications ensure the 16 Wheeler meets rigorous safety and environmental standards. From CSA510 for brake testing to FMVSS structural requirements, manufacturers align production with global regulatory frameworks, ensuring operational compliance across jurisdictions. This standardization builds trust among shippers, carriers, and regulators alike.

<

A full lifecycle analysis reveals that, despite higher initial outlays, 16-wheelers deliver superior total cost of ownership (TCO). According to the Transportation Research Board, fleets report 15–20% lower operating costs over ten years compared to older counterparts, driven by fuel efficiency, durability, and reduced downtime. “The investment in a 16 Wheeler is a strategic move toward future-proofing operations,” states Jessica Lin, Fleet Analyst at Prime Logistics.

“It balances immediate productivity with long-term resilience—key in today’s volatile supply chain environment.” <

Onboard telematics also play a critical role, enabling drivers to adopt fuel-efficient driving habits—reducing not just costs, but carbon footprints. A 2023 study by the International Council on Clean Transportation found that optimized route planning and smooth acceleration patterns can lower emissions by up to 25% on heavy-duty fleets. “Sustainability isn’t optional anymore—it’s part of the 16 Wheeler’s evolution,” says Dr.

Elena Torres, Director of Freight Sustainability at GreenHaul Inc. “We’re measuring success not only by ton-miles moved, but by how responsibly we move them.” The Truck 16 Wheeler, once synonymous with fossil-fuel dominance, now stands at the intersection of industrial might and environmental responsibility—proving that power and sustainability can coexist. In the final analysis, the Truck 16 Wheeler is more than a vehicle.

It is a mobile engineering marvel, built to endure the toughest demands of global logistics while adapting to technological, regulatory, and ecological shifts. Its 16 wheels distribute not just weight, but opportunity—powering economies, supporting supply chains, and setting new benchmarks in heavy transport innovation. As industries evolve, so too does the 16 Wheeler—future-ready, relentlessly efficient, and indispensable.

Related Post

Contexto Answer Warning This Common Mistake Is Killing Your Streak

Shaping tennis’s future: The Women’s Tennis Association’s Lasting Legacy

Unveiling the Gore Video That Shook Qyiero Agua: How Qyiero Agua’s Water Crisis Became a Global Flashpoint

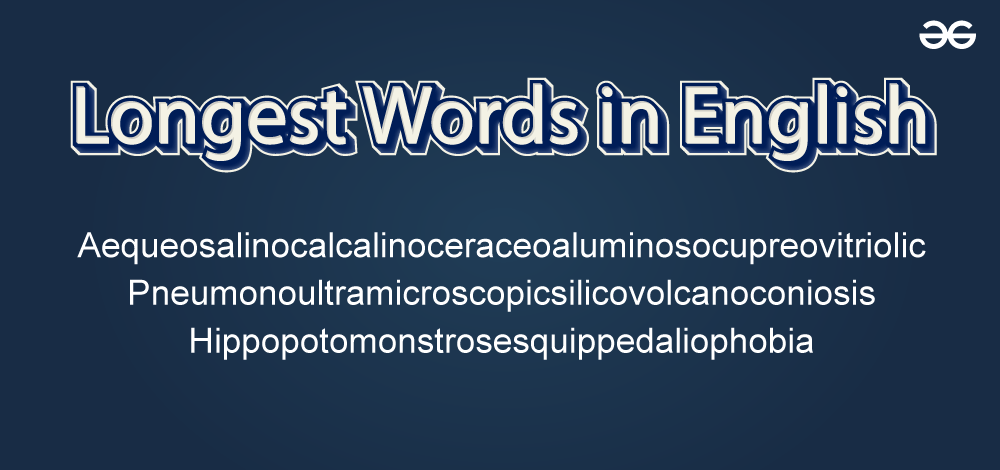

Top 10 Longest Words Ever Written in English: The Obsessive Quest for Linguistic Extremes