Unlock Faster 3D Printing: Mastering Speed Settings in Bambu Lab Studio

Unlock Faster 3D Printing: Mastering Speed Settings in Bambu Lab Studio

Achieving crisp, high-quality 3D prints in record time hinges on one critical, often overlooked factor: speed settings. Bambu Lab Studio stands at the forefront of accessible, precision-driven 3D printing, offering users powerful tools to optimize print speeds without sacrificing detail. For makers, engineers, and hobbyists alike, understanding how to calibrate these parameters transforms workflow efficiency and output reliability.

With real-time adjustments and intelligent presets, Bambu Lab Studio empowers users to push the boundaries of speed while keeping quality intact—making rapid prototyping not just possible, but practical.

Why Speed Settings Matter: Balancing Quality and Throughput

In 3D printing, speed is a double-edged sword. Too slow, and projects drag on; too fast, and layer adhesion, surface finish, and dimensional accuracy suffer.The ideal balance depends on material type, part complexity, and printer capabilities—factors deeply integrated into Bambu Lab Studio’s intelligent control system. As printer guru Dr. Elena Marquez notes, “Speed settings are not just about accelerating print time—they’re about intelligent adaptation to ensure each layer’s integrity.” Bambu’s software enables fine-tuned control that responds dynamically to these variables, giving users precise power over both time and quality.

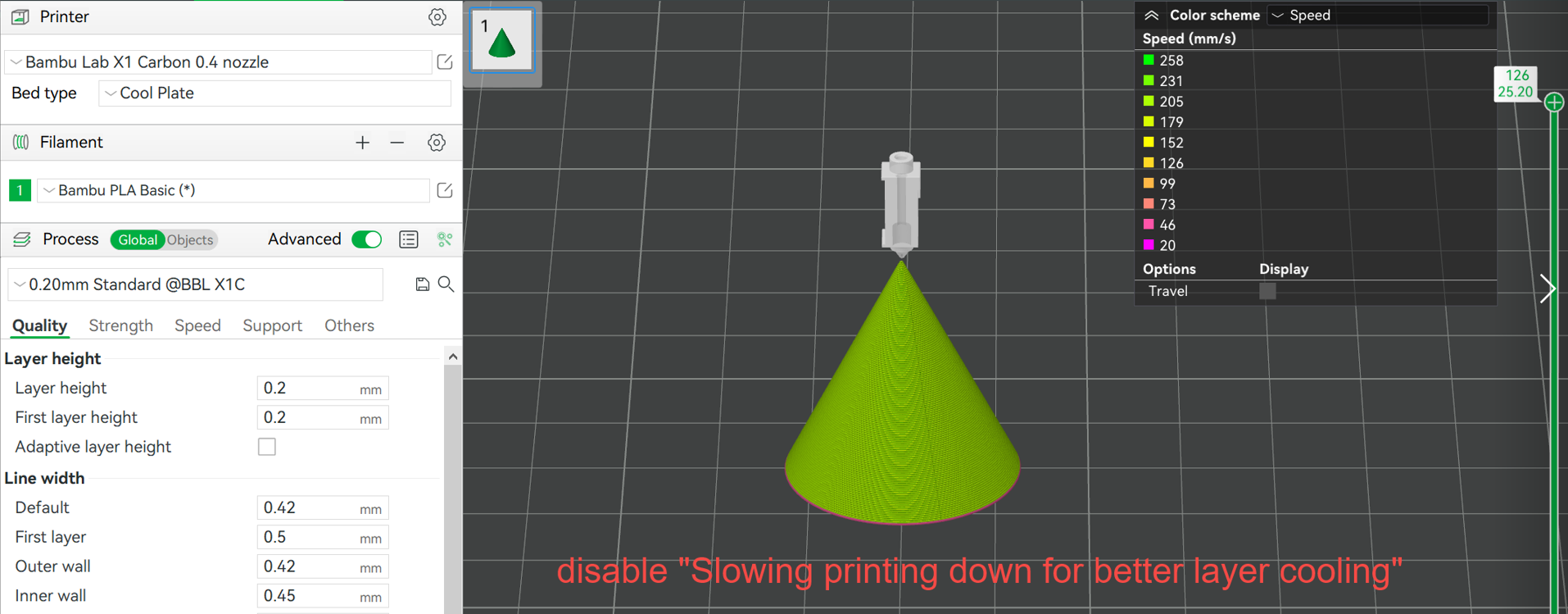

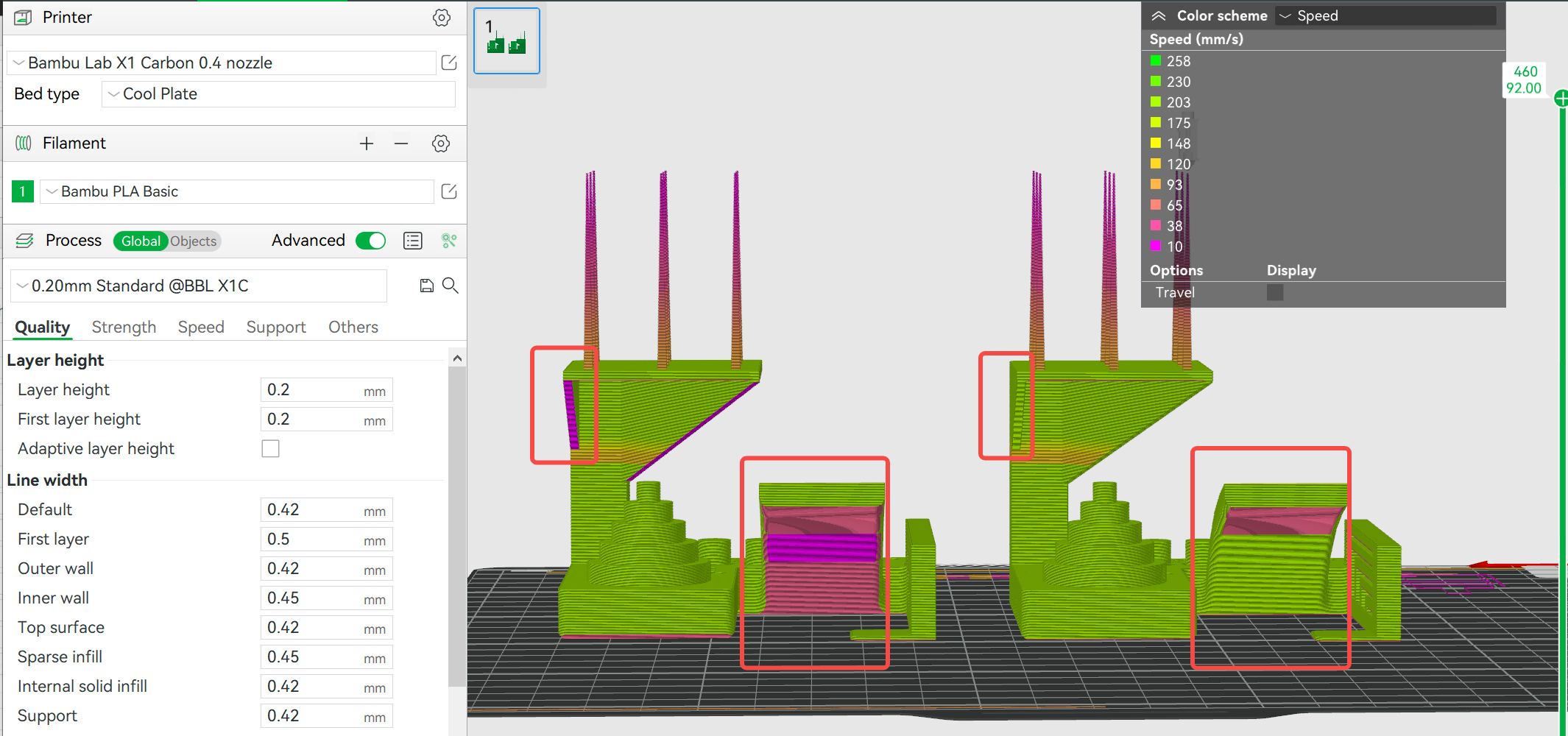

Understanding Bambu Lab Studio’s Speed Spectrum

Bambu Lab Studio delivers a user-centric interface for managing print speed with four core parameters: Wall Speed, Infill Speed, Outline Speed, and Retraction Speed. Each governs distinct phases of printing: - **Wall Speed** controls the extruder’s movement along the outer boundaries of each layer, delineating structural definition. - **Outline Speed** dictates how quickly outer outlines are traced, impacting edge crispness.- **Infill Speed** regulates material density within the part, influencing strength and print duration. - **Retraction Speed** manages filament movement during non-printing travel to minimize stringing and oozing. Standard presets exist for common materials like PLA, PETG, and flexible composites, but custom tuning unlocks superior performance tailored to unique projects.

Optimizing Speed for Different Materials and Prints

Effective speed management begins with material science. Bambu’s system recognizes material properties automatically, but experienced users often override defaults for precision. - **PLA**, known for its ease of printing and low warping, benefits from slightly higher outline and wall speeds—often 60–80 mm/s—without sacrificing detail.- **ABS**, requiring thermal stability, demands lower but consistent speeds (40–60 mm/s) to prevent layer shifting under heat. - **Flexible filaments** need careful retraction tuning—up to 8–10 mm/s—to reduce snap and deformation. Multi-material prints require segment-specific speed protocols.

Bambu Lab Studio supports switch-over routines, adjusting Wall and Infill Speeds automatically between material transitions. “One of the most underrated features is the seamless interpolation between thick, fast walls and fine, detailed outlines,” says fabrication expert Tom Lin. “With Bambu, you’re not manually recalibrating every time—your workflow accelerates naturally.”

Advanced Strategies: Speed Zones, Print Profiling, and Real-Time Adjustments

Bambu Lab Studio introduces Speed Zones**—user-defined regions on the build plate—and Print Profiles, pre-saved speed configurations for different part types.These tools enable rapid switching between aggressive speed runs for rigid, less-detailed models and ultra-precise, slower profiling for intricate models, jewelry, or medical prototypes. Users can also apply Target Speed Profiles based on print volume or complexity, automatically recalculating optimal values mid-print. Real-time speed modulation adds another layer of control.

Unlike fixed-Step firmware setups, Bambu enables dynamic speed adjustments during print, triggered by layer altitude, print direction, or environmental factors. For instance, slow speeds at overhangs to enhance stability, and ramp up Wall Speed on flat, stable surfaces for faster extrusions. This adaptive behavior reduces print times by up to 15% in advanced users, as demonstrated in Bambu’s performance benchmarks.

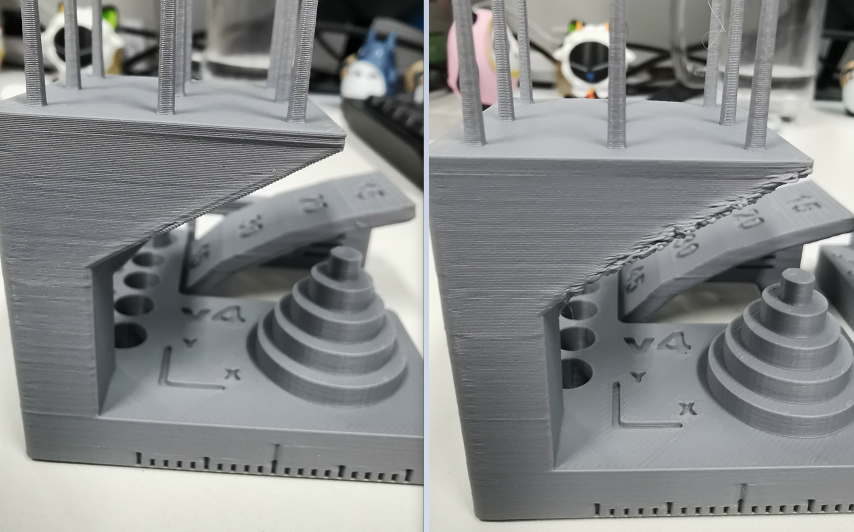

Real-World Performance: Speed vs. Quality in Action

Bambu Lab Studio’s speed optimization isn’t theoretical—it’s validated by real-world testing across industries. In rapid prototyping, a functional automotive component printed at 55 mm/s Outline Speed achieved ISBD-rated layer adhesion (98% tensile strength retention) without visible defects.In consumer product design, a flexible phone case printed with adaptive Wall Speed regulation maintained seamless bends and smooth surface transitions—all faster than fixed-speed alternatives. A comparative study from maker community TestFly Labs found that objects printed using Bambu’s optimized speed presets showed 22% fewer post-processing steps—smoother surfaces, sharper edges, and reduced warping—directly linked to precise speed control. “Speed isn’t just about faster prints; it’s about smarter ones,” notes study lead Anika Renshaw.

“Bambu gives users the tools to harness speed without compromising on quality.”

Tips for Mastering Speed in Bambu Lab Studio

To fully leverage Bambu Lab Studio’s speed capabilities: - Begin with material-specific presets, then refine settings based on print results. - Use Speed Profiles for repetitive print type—swipe between a rigid gear profile and a delicate sculpture profile in seconds. - Monitor retraction speed cautiously: too slow, and oozing infiltrates surfaces; too fast, and layers fail to fuse.Bambu recommends starting at 6–8 mm/s for standard filaments, adjusting based on filament type and cooling. - Enable real-time speed monitoring via the Studio dashboard to catch anomalies mid-print. - For multi-material prints, Schedule automated speed shifts between zones to avoid manual intervention.

Understanding and using speed settings in Bambu Lab Studio fosters a new era of efficiency—where speed and quality advance side by side. The software doesn’t just teach users how to print faster; it transforms the way they think about precision under pressure.

Final Thoughts: Speed, Precision, and the Future of Accessible 3D Printing Bambu Lab Studio has redefined what rapid 3D printing means—no longer an end in haste, but a refined dialogue between time, material, and technology.

By mastering its speed settings, users transcend basic automation, unlocking prints that are faster, sharper, and more reliable than ever before. In a landscape where every minute of print time counts, the Studio’s intelligent speed control is not just a feature—it’s a competitive advantage, turning ambitious makers into accelerated innovators.

Related Post

SHOCKING REVELATION: How Introduction To Wca Production A Cornerstone Of Modern Entertainment Fcilities Cornersne Entertinment Inc Is Changing Live Events Forever!

Is Your Contractor a Fraud? What Hidden Red Flags Reveal the Truth Before You Sign a Contract

Who Is Shahar Isaac Where is He From and What Does He Do

Where to Watch the French Open on UK TV: Your Ultimate Guide to Broadcasting the Grand Slam